Potential Developments in Tire Reinforcement Technologies

13 May 2016

Sadettin Fidan

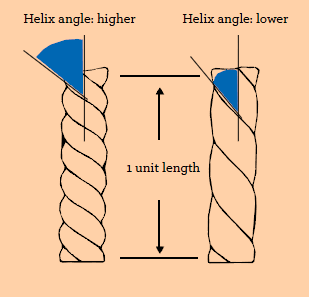

Structurally, a pneumatic tire can be defined as a high-performance composite, comprising polymeric and metallic reinforcements in rubber matrix with functions of load carrying, steering stability, force transmission, impact absorption and comfort, minimum power consumption, endurance and safety. The helix structure or twisted form of the cord reinforcements optimizes breaking strength, modulus and fatigue resistance properties having vital importance on tire performance.

But, when we take a look at the history of the reinforcement developments within last fifty years, although there have been several hundreds of patents on tire reinforcements, we do not see a breakthrough application revolutionizing the tire reinforcement concepts. That is, at least until Kordsa started to focus on innovative and revolutionary tire reinforcement concepts recently.

Low Twist - High Fatigue Resistant Pet Cords Offer New Design Parameters to Tire Manufacturers

Low Twist - High Fatigue Resistant Pet Cords Offer New Design Parameters to Tire Manufacturers

The first of the potential products about to be developed during 2015 is High-TMF cords. High-TMF cords refers to High Tenacity, High Modulus, High Fatigue Resistance Cords and these revolutionary tire reinforcement concepts are in progress in Kordsa.

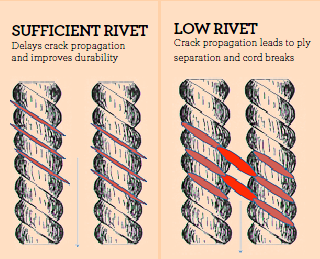

While smaller helix angle enhances braking strength and modulus, the special dip system penetrating through the individual filaments improves the tension, compression and flexural fatigue resistance. Increased breaking strength due to lower twist makes it possible to use thinner cords which leads to rubber saving and rolling resistance reduction. Or by using lower epdm, the increased cord-to-cord distance (rivet) improves tire durability. In terms of High Fatigue resistant cords especially PET Cord as carcass, some potential applications are; High- TMF PET Cord as carcass in radial PC and LT tires, High-TMF NYLON as cap ply in radial PC tires and HIGH-TMF NYLON as carcass and breaker in bias tires.

Also, High-TMF PET Cord can replace rayon carcass in UHP tires (similar trend existed in 2014). Kordsa is working diligently to deliver trial samples at the end of 2015.

The Tire Technologies Should Discover the Unused, But Powerful Properties of Nylon 6.6

The Tire Technologies Should Discover the Unused, But Powerful Properties of Nylon 6.6

The second innovative and revolutionary tire reinforcement concept is SUPER HIGH MODULUS NYLON 6.6. Actually, nylon cord is a bi-elastic or dual-modulus reinforcement within a very wide range of twist, having low initial modulus and high final modulus after a wide transition zone.

Especially in cap ply applications, only low modulus and some parts of the transition zone can be used by almost all of the tire technologies. In order to minimize or prevent the tire growth under high speed conditions, it would have been preferable to use high modulus part of stress-strain curve, enabling a sufficient restraining force together with high thermal shrinkforce with less material. That`s why, in order to offer this hidden and not- used nylon property for tire applications, Kordsa is working to narrow the transition zone between low and high modulus zones of the nylon in stress-strain curve.

This new High Modulus Nylon will have more pronounced bi-elastic behavior like hybrid cords, having nylon like initial modulus and PET like secondary modulus which will be much more effective as cap ply than conventional nylon applications. In Capmax form, super high modulus nylon will not show any cutting effect due to texturized weft`s stress distribution effect on belt layer.

The third innovative and revolutionary tire reinforcement concept is INTELLIGENT (ADAPTIVE) CAP PLY. The Intelligent (adaptive) cap ply reinforcement controls the restraining force as a function of tire speed and, by preventing tire growth, it improves high speed durability. Its response range and profile is controlled by glass transition temperature and polymer morphology. Temperature dependent shrinkforce intensity and modulus change can be tailored by fibers having different Glass Transition Temperatures. Kordsa aims to provide Lab samples for customers within this year.

The third innovative and revolutionary tire reinforcement concept is INTELLIGENT (ADAPTIVE) CAP PLY. The Intelligent (adaptive) cap ply reinforcement controls the restraining force as a function of tire speed and, by preventing tire growth, it improves high speed durability. Its response range and profile is controlled by glass transition temperature and polymer morphology. Temperature dependent shrinkforce intensity and modulus change can be tailored by fibers having different Glass Transition Temperatures. Kordsa aims to provide Lab samples for customers within this year.

And the last of the innovative and revolutionary tire reinforcement concepts is ULTRA HIGH MODULUS POLYMERIC REINFORCEMENT. It seems that, the only way for drastic weight reduction and fuel saving is to replace high density metal reinforcements with low density ultra high modulus fibers as composite strips or as stiff, but flexible, cords. Several tire companies have already tried to find the alternatives and patented them, but most of them were not mature enough to overcome integrity (fiber-fiber separations resistance) and fatigue (e.g., compression induced cracks) problems under dynamic conditions in tire.

Obviously, a belt package made of UHM polymeric cords might require a strong cap ply for a sufficient plunger energy. UHM cords provide sufficient breaking strength and modulus as bead core, but 3 to 5% breaking elongation and radial (tranverse) toughness is also needed for tire mounting and demounting. Steel cord and textile combinations which are able to increase their stiffness as a function speed and temperature could find application as belt package in passenger car tires in future (intelligent belt layers).

Kordsa aims to provide trial samples for tire companies within this year. Kordsa continues to make developments for creating value added products according to the trends in tire industry.